Our Capabilities As A Worm Gear Manufacturer

Worm gears are usually used when large speed reductions are needed. The reduction ratio is determined by the number of starts of the worm and number of teeth on the worm gear.

Worm gears have sliding contact which is quiet but tends to produce heat and have relatively low transmission efficiency.

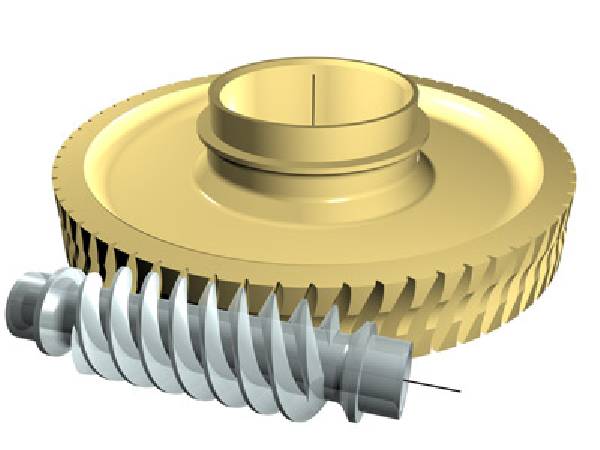

Worms and worm gears are gear sets that offer high gear reduction and torque multiplication with a small footprint. A worm drive is a cylindrical gear with a shallow spiral thread that engages the worm gear in a non-intersecting, perpendicular axes configuration.

Worm gears are the most compact type of system and provide high-ratio speed reduction. They are often the preferred type of gearing system when space is limited and large gear reductions are needed.

Worm gears can be used to either greatly increase torque or greatly reduce speed. They are also the smoothest and quietest of the gear systems, as long as they are properly mounted and lubricated.

Efficiency of a worm drive is determined by the lead angle and the number of threads in contact with the worm gear.

-

A high lead angle on the drive reduces frictional losses and heat. A low lead angle reduces gear speed while proportionally increasing torque.

-

Friction is an issue with all worm sets; the worm gear cannot transfer motion back to the worm drive in most instances.

-

Lubrication and precision cut teeth both contribute to the sets’ overall silence while minimising friction. Worm gear sets are usually produced in pairs due to their precision.

As A Worm Gear Manufacturer We Manufacture The Following Types Of Worm Gears.

Non-enveloping worm gear sets do not have concave features and the straight plane of contact between gears places the highest level of stress on the gear teeth.

As for the materials for production, in general, worm is made of hard metal while the worm gear is made from relatively soft metal such as aluminum bronze.

Single-envelop worm gear sets contain a worm gear with a concave tooth width, allowing the worm drive to nestle into the gear and increasing efficiency.

As for the materials for production, in general, worm is made of hard metal while the worm gear is made from relatively soft metal such as aluminum bronze.

Double-envelop worm gear sets contain both a word gear with a concave tooth width, and a worm drive with a concave profile. This design maximizes efficiency.

As for the materials for production, in general, worm is made of hard metal while the worm gear is made from relatively soft metal such as aluminum bronze.